Introduction: Quiet, Safe, and Florida-Tough

In Florida, a garage door is not only a daily convenience; it is a safety device and a weather barrier. Heat, humidity, coastal salt, and seasonal storms can make a door louder and less predictable over time. The right steps will reduce noise, protect moving parts, and preserve critical safety systems that prevent injuries. This comprehensive guide focuses on practical, Florida-specific steps that make your door quieter and safer without straying into tasks that require specialized tools. For homeowners who prefer extra assurance and calibration by a trained eye, schedule periodic garage door maintenance to complement your routine and keep performance consistent across the seasons.

The plan below concentrates on the highest-impact tasks: cleanliness, controlled lubrication, alignment verification, safety sensor reliability, and manual operation checks. You will also learn to diagnose noise sources, choose better components for humid climates, and avoid common mistakes that make a door louder or less safe.

Step 1: Start With Cleanliness

Dirt, sand, and salt are the enemies of quiet operation. Begin by washing the door panels with mild detergent, rinsing thoroughly, and drying exposed hardware. Wipe the tracks with a dry cloth to remove grit; do not apply lubricant in the channel. Clean the bottom seal and threshold to remove debris that prevents complete closure. A clean, dry system runs quieter and lets you hear genuine problem sounds instead of normal movement masked by grit.

Step 2: Inspect and Tighten Accessible Hardware

With the door closed, inspect hinge screws, track bracket bolts, and opener mounting hardware. Tighten loose fasteners carefully, avoiding over-torque that could strip holes in wood or thin metal. Pay extra attention to the top bracket where the opener arm attaches to the door; this point sees repeated force and must remain solid. Eliminating looseness reduces rattles and vibration transmitted into the framing.

Step 3: Targeted Lubrication for Quiet Operation

Use a light, garage-door-specific lubricant on pivot points: hinge pins, roller bearings, and spring bearings. Apply sparingly and wipe excess to prevent drips and dust collection. Silicone-spray the side, top, and bottom weather seals to keep rubber pliable and quiet during hot, sticky afternoons. Do not lubricate inside the track; a clean track paired with lubricated rollers yields the quietest outcome.

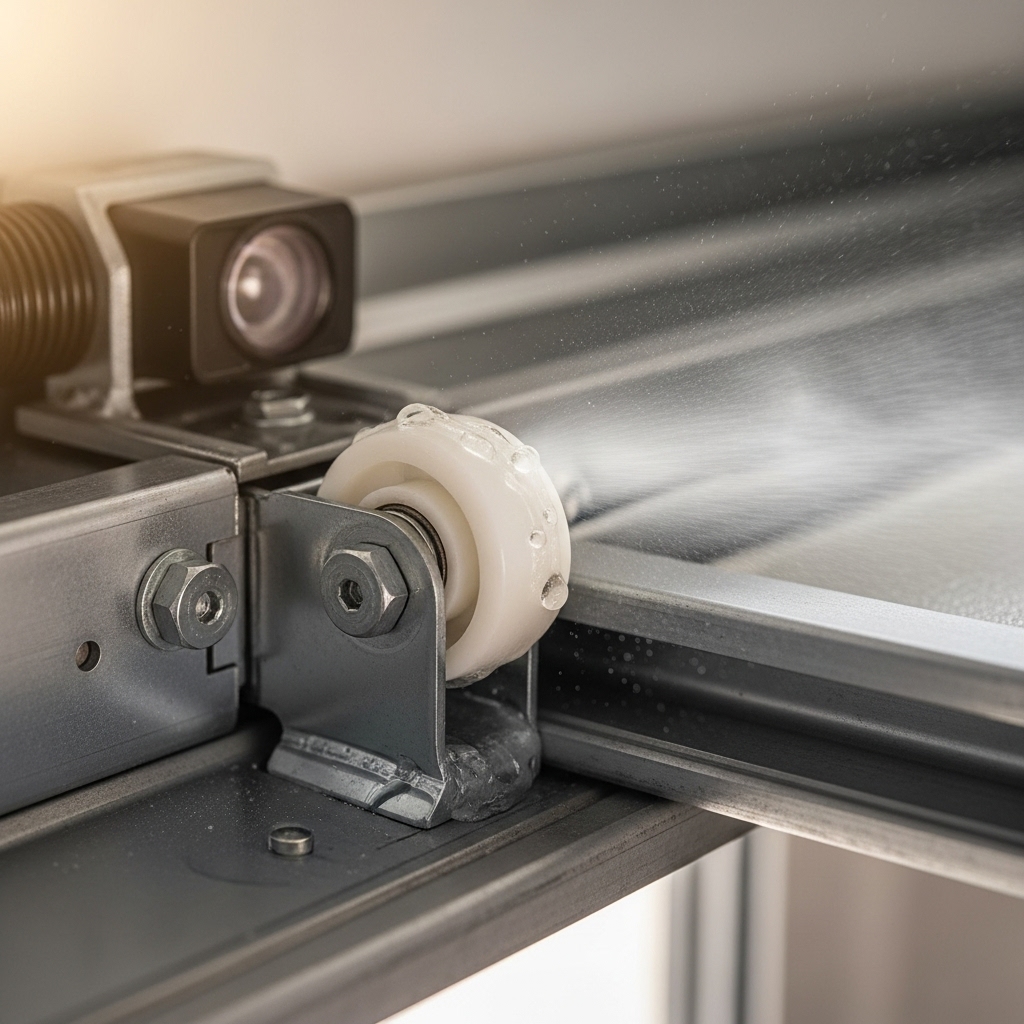

Step 4: Roller and Hinge Health

Rollers and hinges shape the door’s sound profile. Nylon rollers with sealed bearings are best for humid climates; they resist corrosion and roll quietly. Replace rollers that wobble, squeal persistently after lubrication, or show cracked nylon. Inspect hinges for hairline cracks and elongated holes. Worn hinges allow sections to shift under load, creating knocks and rattles. If you replace hardware, choose corrosion-resistant materials whenever possible to stand up to Florida’s humidity and coastal air.

Step 5: Track Alignment and Support

A misaligned track causes scraping, pops, and jerks. Confirm vertical tracks are plumb and horizontal tracks are level and properly supported. If a section binds or scrapes, loosen the appropriate fasteners while the door is secured, gently realign, and retighten. Ensure the track flanges are straight and free of dents. Solid alignment reduces noise and extends component life by minimizing side loads on rollers and hinges.

Step 6: Opener Calibration and Vibration Control

Openers that are out of calibration tend to be loud and unsafe. Test safety reversal by closing the door on a 2×4 laid flat; the door should reverse upon contact. Adjust force and travel settings per the opener manual if needed, or call a professional if results remain inconsistent. Check the opener’s header bracket and ceiling support angles; tighten if you see movement. Reduce vibration by ensuring the rail is straight and the trolley moves smoothly. Where appropriate, consider vibration-isolating mounts recommended by the manufacturer to dampen noise transferred into the structure.

Step 7: Sensor Reliability Under Florida Sun

Photo-eye sensors can be finicky in bright, reflective environments. Clean lenses, verify alignment, and ensure indicator lights are solid. If afternoon sun floods the garage, add shading or adjust sensor angles slightly to reduce glare. Keep boxes, tools, and beach gear out of the sensor path; unnecessary obstructions cause nuisance reversals and noisy restarts.

Step 8: Manual Operation and Balance Check

Unplug the opener, ensure the door is down, and pull the emergency release. Lift the door by hand; it should stay near the halfway point if balanced. A door that falls or surges indicates spring imbalance, which strains the opener and becomes a safety risk. Do not attempt spring adjustments yourself—call a trained technician. Reconnect the opener and confirm smooth travel and proper stopping points.

Step 9: Weather Seal Care for Quieter Closings

Worn seals create slapping sounds, poor closure, and air leaks that whistle during gusty weather. Clean the bottom seal and side/top seals with mild soap and water, then apply silicone to preserve flexibility. Replace seals that are cracked, hardened, or failing to block light. A compliant, soft seal cushions contact and quiets the final moment of closure while keeping wind-driven rain and pests out.

Step 10: Corrosion Prevention in Humid and Coastal Areas

Salt and humidity attack exposed metal, creating squeaks and grinding over time. Wipe surfaces dry after washing and apply a thin anti-corrosion film to fastener heads, the torsion shaft ends, and bracket edges as needed. Avoid heavy coatings that fling off and make a mess. Consider upgrading to corrosion-resistant fasteners and sealed-nylon rollers to reduce long-term maintenance and noise.

Step 11: Seasonal Routines for Florida

Monthly: Inspect, clean, and lubricate. Test safety reversal and verify sensor alignment. Quarterly: Deep clean, check opener mounts, confirm track alignment, and re-evaluate weather seals. Pre-storm season: Validate reinforcement struts and manual operation readiness. After severe weather: Rinse salt and debris, re-lubricate pivot points, and inspect alignment and panel integrity.

Diagnosing Common Noises

Squeak at mid-raise: Often a dry hinge or roller bearing—apply a small burst of lubricant and wipe excess. Scrape near the top: The door may be racked or the horizontal track misaligned—inspect track supports and realign gently. Rattle throughout travel: Loose opener mounts, track brackets, or reinforcement struts—tighten and verify the rail is straight. Thump at closing: A flattened bottom seal or mis-set travel limit—replace the seal or adjust per the opener manual.

What Not to Do

Do not lubricate the track channel; it attracts dirt and increases noise. Do not use heavy grease that thickens in heat. Do not disable safety sensors to close the door. Do not attempt spring or cable adjustments. Do not ignore frayed cables, cracked hinges, or rollers that wobble.

When to Seek Professional Help

Call a professional if the door is out of balance, binds even after alignment, or fails safety reversal consistently. Seek help if you notice frayed cables, bent tracks, or persistent grinding that returns soon after lubrication. A trained technician can replace worn bearings, verify spring torque, and calibrate opener settings precisely—essential steps for lasting quiet and safety.

For homeowners who appreciate a blend of DIY care and expert calibration—especially in Florida’s demanding climate—schedule thorough garage door maintenance to validate alignment, confirm spring balance, and fine-tune opener operation. Pairing your steps with professional insight keeps noise low and safety high.

Frequently Asked Questions

Q: What lubricant is best for quiet operation in Florida? A: A light, non-detergent lubricant designed for garage door hardware on hinges and rollers, with silicone on weather seals. Avoid heavy grease and general-purpose oils.

Q: How can I reduce opener noise? A: Verify rail straightness, tighten mounts, use manufacturer-approved vibration isolation, and confirm proper force and travel settings. Belt-drive openers are typically quieter than chains.

Q: My door is balanced but still noisy. What next? A: Replace worn rollers with sealed-nylon units, inspect hinges for cracks, and confirm track alignment. Persistent noise may come from worn spring or end bearings that require professional replacement.

Q: Why does my door reverse randomly in the afternoon? A: Sun glare can interfere with photo-eyes. Clean lenses, realign, and add shading if necessary. Ensure storage items are not in the beam path.

Q: Are coastal upgrades worth it inland? A: Yes. Corrosion-resistant hardware and sealed-nylon rollers perform well statewide, not just at the beach. They often reduce noise and extend service life.

Q: How often should I do these steps? A: Monthly for inspection, cleaning, lubrication, and safety tests; quarterly for deeper checks; and before storm season for reinforcement and manual operation readiness.

Make Your Florida Garage Door Quiet and Safe

With regular cleaning, targeted lubrication, careful alignment, and reliable safety checks, your garage door can remain quiet and predictable in Florida’s challenging environment. For precision calibration and component assessments that go beyond DIY, book expert garage door maintenance and enjoy confident, smooth operation every day.